What is a Bent Wheel Repair Machine?

In the automotive repair industry, a bent wheel repair machine is essential for repairing and restoring bent or deformed wheels. Wheels are critical components of a vehicle as they directly contact the ground, and their condition greatly influences driving safety, vehicle performance, and handling. Regular driving on rough roads, potholes, or collisions can cause wheels to bend or deform. If these issues are not addressed promptly, bent wheels can lead to severe problems such as vehicle vibrations, uneven tire wear, pulling to one side, reduced stability, and even dangerous situations like tire blowouts that threaten passenger safety.

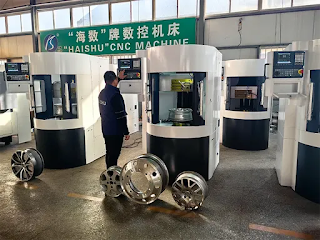

The bent wheel repair machine is designed to address these problems efficiently. It can accurately detect the location and degree of bending and uses advanced tools such as hydraulic reshaping systems and mechanical clamps to restore the wheel’s shape. Repaired wheels regain their dynamic balance and structural integrity, ensuring safe and smooth driving. Among the leading wheel repair lathes (Máquina de reparación de ruedas)and wheel CNC machine (पहिया मरम्मत मशीन) manufacturers, Taian Haishu stands out as a trusted brand offering high-quality car wheel repair lathes, aluminum wheel repair machines (آلة إصلاح العجلات), and other advanced equipment.

How Does a Bent Wheel Repair Machine Work?

The Basic Principle of a Bent Wheel Repair Machine

The working principle of a bent wheel repair machine revolves around hydraulic pressure and precise adjustments. The machine’s hydraulic system provides power, allowing a pressing head or mechanical arm to apply controlled force to the bent portion of the wheel. By setting parameters, the wheel is gradually reshaped to its original form. Technicians use tools such as magnetic dial indicators to monitor the process and ensure precision.

In some cases, when the wheel becomes too rigid due to cooling, a heat gun is used to soften the metal before further hydraulic reshaping. This process is typically repeated several times, taking approximately 30 minutes to complete.

Repairing Cracks in Aluminum Wheels

In addition to reshaping bent wheels, the aluminum wheel repair machine can fix cracks in the wheel caused by impact or wear. This involves aluminum welding to fill the cracks, followed by machining to remove excess material. For this, a wheel repair lathe (Máquina de reparo de rodas)equipped with turning capabilities is often used to ensure a smooth finish and proper balance.

The Role of Wheel Balancing

After completing the repair process, wheels are tested for dynamic balance using specialized equipment. A properly balanced wheel ensures a stable ride, minimizes vibrations, and reduces wear on tires and suspension components.

What Are the Types of Bent Wheel Repair Machines?

Manual Bent Wheel Repair Machines

Manual bent wheel repair machines are operated entirely by hand. They are simple, cost-effective, and suitable for small repair shops or businesses where repair precision is not a top priority. However, technicians using manual machines need considerable expertise to apply the correct amount of force and adjust the direction for accurate repairs.

Semi-Automatic Bent Wheel Repair Machines

Semi-automatic wheel repair lathes (Станок для ремонта колес) and machines combine manual operation with automated features. For example, they may include motorized wheel rotation or automatic measurement of bending data. These machines improve repair efficiency and precision while maintaining flexibility. They are ideal for medium-sized repair businesses looking for a balance between cost and performance.

Fully Automatic Bent Wheel Repair Machines

Fully automatic bent wheel repair machines, such as the wheel CNC machine (Machine de réparation de roues), integrate advanced technology like computer-controlled systems and high-precision sensors. These machines can automatically detect wheel damage, process repair data, and complete the entire repair process with minimal human intervention. Fully automatic machines are highly efficient, precise, and reliable, making them the preferred choice for large repair centers and automotive manufacturers. However, their high cost and sophisticated operation requirements make them less suitable for smaller businesses.

What Are the Features and Specifications of Bent Wheel Repair Machines?

Common Specifications

The specifications of a bent wheel repair machine vary based on the model and type. However, here are some common parameters:

- Repair Size: 10 inches to 26 inches (extendable to 30 inches for specific needs).

- Working Pressure: Around 10,000 kilograms.

- Motor Power: Typically 1.5 kW and 0.75 kW.

- Machine Weight: Approximately 360 kg.

- Key Features: Hydraulic reshaping, aluminum welding capabilities, dynamic balancing tools, and cutting functions for excess material removal.

Taian Haishu RSM595 Technical Parameters

One of the standout products in the market is the Taian Haishu RSM595 aluminum wheel repair machine. Its technical parameters include:

- Maximum Wheel Diameter: 30 inches.

- Motor Power: 2.2 kW.

- Hydraulic Pressure: 12,000 kilograms.

- Machine Weight: 450 kg.

- Additional Features: Integrated CNC system, high-precision sensors, and advanced reshaping tools.

This versatile machine provides outstanding performance and is highly recommended for professional repair centers.

How to Use a Bent Wheel Repair Machine?

Preparation Work

- Inspect the wheel repair lathe (Rad reparatur maschine)or wheel CNC machine (휠 수리 기계) to ensure it is functioning correctly.

- Clean the wheel’s surface to remove dirt and debris.

- Install the necessary clamps and measuring tools.

Wheel Inspection

Use a magnetic dial indicator to check the wheel for bends, deformation, and cracks. Record the specific location, angle, and degree of bending to create a repair plan.

Repair Process

- If needed, preheat the wheel using a heat gun to soften the material.

- Apply hydraulic pressure to reshape the bent part of the wheel gradually.

- For cracks, perform aluminum welding and use a wheel repair lathe (Tekerlek tamir makinesi) to remove excess material.

- Repeat the above steps until the wheel is fully restored, which usually takes about 30 minutes.

Post-Repair Testing

Once the repair is complete, test the wheel using a wheel balancing machine to ensure it meets safety and performance standards.

How to Maintain a Bent Wheel Repair Machine?

Regular maintenance is essential to extend the lifespan and ensure the performance of your bent wheel repair machine.

Key Maintenance Steps

- Follow the manufacturer’s manual for maintenance schedules and procedures.

- Regularly check and refill hydraulic oil and lubricants.

- Replace worn-out components promptly to avoid machine damage.

- Clean the machine after each use to prevent debris buildup.

Taian Haishu provides detailed maintenance guidelines for their products, ensuring customers can maximize the value of their wheel repair machines.

Why Choose Taian Haishu Bent Wheel Repair Machines?

Industry Leadership

Taian Haishu is a leading manufacturer of wheel repair lathes (Máy sửa chữa bánh xe), wheel CNC machines, and other automotive repair equipment. Their products, such as the RSM595 aluminum wheel repair machine, are known for their reliability, precision, and advanced features.

Benefits of Choosing Taian Haishu

- High Quality: All machines are built with durable materials and cutting-edge technology.

- Comprehensive Support: Taian Haishu offers excellent customer service, including training and after-sales support.

- Customization Options: Machines can be tailored to meet specific customer requirements.

Clients are welcome to visit Taian Haishu’s facilities to see their state-of-the-art manufacturing process and test their products.

What Are the Benefits of Bent Wheel Repair Machines in the Automotive Industry?

Enhanced Safety and Performance

By restoring the shape and balance of bent wheels, these machines improve driving safety and the overall performance of vehicles.

Cost-Effective Solution

Repairing wheels with a car wheel repair lathe (Mesin pembaikan roda) or aluminum wheel repair machine is more cost-effective than replacing them, saving money for both repair shops and car owners.

Wide Range of Applications

From passenger cars to trucks, wheel repair machines can handle a variety of wheel sizes and materials, making them versatile tools for the automotive repair industry.

Conclusion

A bent wheel repair machine is an indispensable tool for automotive repair businesses, ensuring wheels are restored to their original shape and balance. Whether you need a manual wheel repair lathe, a semi-automatic wheel CNC machine, or a fully automatic solution like the Taian Haishu RSM595, there are options to suit every need.

With advanced technology, exceptional quality, and reliable customer support, Taian Haishu is the go-to brand for professional and efficient wheel repair solutions. Investing in their machines will enhance your repair services, improve customer satisfaction, and give you a competitive edge in the market.