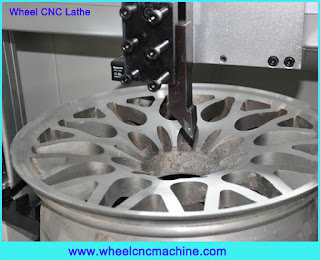

Automatic Wheel Repair Lathe CKL-35 is a special wheel CNC machine for wheel repair. The vertical wheel repair lathe has a cast steel frame with good looks and is rounded off with our HAISHU software, and it is equipped with a liquid crystal touch screen operation. This wheel lathe overcomes the universal system’s shortcomings for wheel repair which has the characteristics of professionalism, full functions, good performance, ease of operation. The vertical wheel surface CNC lathe is fast, automatic, and easy to use with technical support and training. The wheel repair lathe can cut wheels and store profiles on the system to build up your very own wheel profile library – saving your time! This vertical wheel repair lathe is reliable, high configuration, low price.

Our Turkey customer has already bought our wheel CNC lathe a few years ago. Now he needed a new wheel repair lathe for his 4S shop after he tested our system and software. He requested an Automatic Wheel Repair Lathe for the same wheel size as before. We chose Automatic Wheel Repair Lathe CKL-35 for him. After checking the operating video of our wheel lathe, he was very satisfied. After they saw the parameter he wanted to order one set immediately and asked for the PI.

After the Automatic Wheel Repair Lathe CKL-35completed, we sent them the Wheel Surface Repair lathe test video and detailed pictures. They are looking forward to receiving the new machine and putting it into use soon.

|

| 添加图片说明 |

Alloy Wheel Lathe CKL-35 Specifications

| Item | Unit | Specifications |

| Model | Vertical Wheel Repair Lathe CKL-35 | |

| Max. turning diameter | mm | 1000 |

| Max. machining wheel diameter | mm | 900 |

| Chuck maximum clamping diameter | mm | 920 |

| Spindle speed (frequency conversion) | rpm | 50-1200 |

| Turret vertical movement distance | mm | 450 |

| Tool handle section | mm | 25×25 |

| Main motor power | KW | 5.5 |

| Positioning accuracy | mm | 0.015 |

| Repeated positioning accuracy | mm | 0.012 |

| Machine Weight | kg | 1500 |

| Machine Size | mm | 2000*1500*2000 |

| Column 1 Value 13 | Column 2 Value 13 | Column 3 Value 13 |

Wheel Lathe CKL-35 Features

- Newly developed Vertical Rim Turning Lathe CKL-35 by HAISHU Machinery for alloy car wheel repair and superfinishing.

- Cast iron bed. The wheel repair CNC lathe bed is made of cast steel in a vertical structure.

- Large wheel processing diameter. The max wheel processing diameter is up to 35 “.

- Self-developed special wheel repair control software. Automatic wheel surface measurement and program optimization can be realized simultaneously.

- Laser non-contact measurement or probe contact measurement is optional. Laser measurement enables fast scanning.

- Teaching function. The overall wheel surface can be repaired, but also can be partially repaired.

- LCD touch screen configuration

- Compared with the horizontal structure, the mechanical transmission is more stable, the turning performance is better and the machining precision is higher.

- Small machine tool space, professional Vertical Rim Turning Lathe for wheel repair.

- Professional after-sale service including software free upgrade and remote operation and technical training on the wheel CNC machine’s LCD display.

- High performance, cost-effective.

Automatic Wheel Repair Lathe CKL-35 Configurations

- CNC system: “HAISHU” LCD touch screen CNC system

- Laser probe

- Precision spindle unit

- Z-axis dual servo motor drive

- X, Z-axis linear guide

- Precision screw vice

- Software and hardware limit

- Rail protection system

- Automatic lubrication system

- Air cooling system

- Air gun

- MPG

- Warning lights

- Full protection outer casing

- Chip removal box

- Pneumatic door

- Long jaw chuck

- 2 Station row turret

- Z safety brake

Automatic Wheel Repair Lathe CKL-35 Applications

Rim Turning Lathe CKL-35 is the best wheel CNC machine to repair and process the alloy car wheel surface, center hole, and rim, etc.

About Haishu Machinery

Haishu Machinery is a modern professional company specialized in R&D, manufacturing, sales, technical training, and import trade of automotive Smart Wheel Surface Repair CNC Lathe. Since its inception, our company has established long-term strategic partnerships with a number of world-renowned American automotive professional maintenance companies. We have introduced and digested world-leading automotive aluminum alloy wheel repair technologies and processes, filling a number of Chinese automobile wheels. To repair the gaps in the project, the company is determined to explore the professional Alloy Wheel Surface Repair lathe machine in China and lead the wheel repair trend. It is a truly green energy-saving and environmental protection enterprise that repairs old wheels and turns waste into treasure.