Custom Wheel Repair Machine CK6160W is the first and the best dedicated CNC wheel lathe for the rim repair industry since the year 2000. Our wheel repair lathe comes with the most user-friendly touch screen control system providing simple and easy operations. The custom wheel repair machine is equipped with self-developed unique systems and “HSAISHU” software specially designed for wheel lathes. More than 30 countries have our agents, most professional rim shops use our wheel CNC lathes because of the high quality and good performance. The wheel lath is guaranteed to reproduce the factory or better quality finishes on rims.

Our Vietnam customer has already purchased several Alloy Wheel Repair Equipment from us. This time he needed a customized wheel CNC lathe for special wheels. After confirming the max wheel size and thickness, we chose Alloy Wheels Lathe CK6160W and we can customize lengthen the Z-axis travel for his special wheels. They are particularly grateful that we have helped them solve long-standing problems. They wanted to pay the deposit immediately. We sent the PI to them and started preparing the Custom Wheel Repair Machine Equipment CK6160W.

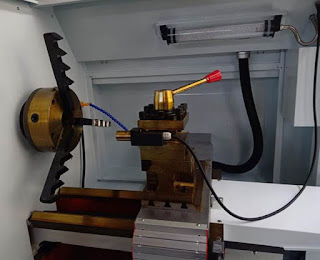

After the Diamond Cutting, Alloy Wheels Lathe CK6160W completed, we sent them the Alloy Wheel Surface Repair lathe test video and detailed pictures. He was very satisfied.

Custom Wheel Repair Machine CK6160W Specifications

| Item | Unit | Specifications |

| Max Wheel Diameter | inch | 22″ |

| X-axis maximum stroke | mm | 320 |

| Main motor power | kw | 3 |

| Rial Width | mm | 260 |

| Max. workpiece length | mm | 500 |

| Wheel measuring direction | X, Z | |

| Measuring Tool | Laser or probe (optional) | |

| Measurement method | Point measurement and a quick scan | |

| Program optimization | Manual and automatic | |

| Number of wheel processing programs | rows | 100000 |

| CNC System | “HAISHU” special system (touch screen operation, 17 “screen LCD display). Universal CNC system (key operation, 10.4 “screen LCD display) (optional) | |

| Wheel processing | Surface, rim | |

| Machining accuracy | um | IT6~IT7 |

| Main drive form | Frequency control, servo drive (optional) | |

| Spindle speed | Factory setting 150~2800 | |

| Fast-moving feed | mm/min | X:5000 Z:8000 |

| Repeat accuracy | mm | X :0.01 Z :0.015 |

| Turret form | Fixed turret,Electric turret (optional) | |

| Section of the turning tool | mm | 25×25 |

| Machine size(L×W×H) | mm | 1900×1400×1750 |

| Net weight | kg | 1300 |

Custom Wheel Repair Machine CK6160W Features

1.The Wheel Machine has the advantages of simple structure, low cost, and high-performance price ratio.

2.The Diamond Cut Wheel lathe can be selected by laser scanning or probe click measurement.

3.Wheel data is automatically stored, the machining program is arbitrarily called out.

4.Software independent development, program automatically optimize

5.Wheel processing is automatic precise and fast

6.The wheel CNC lathe is operated by a touch screen, and the system interface supports many languages.

7.X / Z-axis measurement, wheel surface, and circumferential machining.

8.The wheel repair Machine is equipped with an automatic lubrication system.

9.The Wheel CNC Machine with diamond tool turning, make wheel surface more smooth.

10.The Alloy Wheel lathe machine has the teaching function of the computer.

11.The Wheel Surface Repair lathe can be customized according to customer requirements.

About Haishu Machinery

Haishu Machinery is a modern professional company specialized in R&D, manufacturing, sales, technical training, and import trade of automotive Diamond Cutting Alloy Wheels Lathe. We offer state of the art Rim & Wheel Straightening Machine, High Tech CNC Wheel lathe machines, Precision Diamond Cutting CNC lathes, Rim Refinishing CNC Wheel Repair lathes, and top-quality Alloy Wheel Repair Equipment. We also can customize a special wheel CNC lathe according to the customer’s request.

Our Alloy Wheel Repair Machine with Hi-Tech & Professional & Top Quality widely used by professional rim shops worldwide and famous automobile and wheel manufacturers. If you wanted to start up an alloy wheel repair business, or to repair and refurbish damaged machined/polished alloy wheels, please contact us, We will offer an amazing alloy wheel lathe for you.