Wheel drawing is the process of repairing and modifying different wheels. The grinding product forms lines on the surface of the workpiece, which makes the wheel more beautiful three-dimensional after the drawing process, and the wheel repair lathe can relatively extend the service life of the wheel.

You can create wheel drawing with CAD software by yourself. Another choice is to create wheel drawing with HAISHU CNC wheel software. Our self-developed software can generate the drawing by automatic laser scanning method.

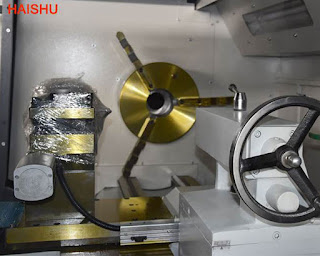

Wheel Drawing Process

Wheel drawing is a treatment method with a decorative effect. Wheel CNC lathe needs to be repaired and refurbished for its surface scratches. Secondly, use a wheel shaping machine for professional plastic repair on the edge of the wheel. Finally, the drawing process is performed, and then the color of the wheel is changed. The color you like makes the personalization of the wheel instantly visible. Car owners generally choose to brush the wheels because the brushed tires seem to have two colors, and the surface has a shiny feeling, which is full of dynamics.

Wheels are also called rims, wheels, and tire bells. They are cylindrical metal parts that support the tire and are mounted on the shaft at the center of the tire. There are many types of wheels according to the diameter, width, molding method, and material. Because the surface drawing process can reflect the texture of metal materials, it has been favored by more and more users and is more and more widely used.

About HAISHU

Taian Haishu is a company specializing in the production of wheel repair lathes. Our product can complete the detection in 10 seconds. Automatically optimize the curve and generate the program. We also own vertical wheel hub lathes, which have been sold in large quantities in Europe and the United States. If you want to know more about wheel repair machine product information, please contact me.