Car Wheel Repair Machine CK6180W is produced by Haishu Machinery CO,.LTD since 2010, with high precision, cost-effective and space-saving. widely used in automobile 4S shop, wheel repair shop, etc. Our Car Wheel Repair Machine is composed of self-made mechanical parts such as the cast steel bed, spindle, fixing chuck and the feeding mechanism, the imported numerical control system,the automatic measuring system, the famous brand servo motors and the auxiliary parts like lubrication, light, and cooling. These Car Wheel Repair CNC Lathes are your best choice for wheel CNC machining, super-finishing, and maintenance.

JIM has 4 auto repair shops in South Korea, specializing in repairing alloy wheels for customers. He met a friend at his friend’s fully automatic wheel repair equipment, automatic detection, automatic turning, and wheel repair. The effect is very good. He asked his friends for my contact information, and then sent me an email asking about the status of the automatic wheel repair equipment. I first asked about the size of his wheel hub. His largest wheel hub is 28 inches. I recommended to him two automatic repair machines, CK6180A and CK6180W. The maximum machining size of both types of wheel turning equipment is 28 inches, but the sheet metal and motor power are different. CK6180W board is better, the motor is 11KW. The motor of the CK6180A is 7.5KW. I sent JIM the technical parameters and photos and processing videos of the two devices. In the end, JIM chose CK6180W, we signed the contract and received the deposit a few days later.

After 30 days, we finished the Car Wheel Repair Machine CK6180W. JIM couldn’t come to our factory to check the wheel lathe, so I sent to him the pictures and testing video of the wheel repair lathe. He told me that it was OK. And then he paid the balance payment. We arranged the shipment.

After 30 days, we finished the Car Wheel Repair Machine CK6180W. JIM couldn’t come to our factory to check the wheel lathe, so I sent to him the pictures and testing video of the wheel repair lathe. He told me that it was OK. And then he paid the balance payment. We arranged the shipment.

Car Wheel Repair Machine CK6180W Technical Parameters

| Item | Unit | Specifications |

|---|---|---|

| Max. turning diameter over the bed | inch | 31 |

| Machining diameter of the wheel | inch | 26 |

| Max. machining length of the workpiece | mm | 750 |

| Surface roughness | um | Ra0.8~0.1 |

| Range of spindle speed | rpm | 150-2000 |

| Main motor power | Kw | 11 |

| Fast-moving feed | mm/min | X – axis:5000 Z – axis:8000 |

| Repeat positioning accuracy | mm | X – axis:0.01 Z – axis:0.015 |

| Standard accessories | 4 station electric tool | |

| Repeat positioning accuracy | mm | 0.008 |

| Section of turning tool | mm | 25×25 |

Car Wheel Repair Machine CK6180W Main Features

◆Wheel repair special CNC lathe. The new design, new structure, new technology.

◆Achieve the wheel surface profile measurement and data collection and Program Optimization.

◆Automatic precision repair and machining by the curve of the wheel surface.

◆Self-developed curve optimization software. Multilingual language interface. Installation and operation are simple.

◆Spindle frequency stepless speed.

◆X / Z-axis servo drive.

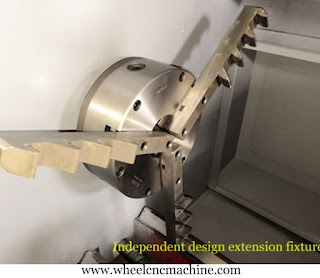

◆Manual jaw self-centering chuck.

◆Machine guard full protection.

◆Security and fault alarm indication.

◆Automatic oil lubrication.

◆Diamond turning, to achieve high-precision smooth machining on the wheel surface.

Uses

◆The machine tool suitable for High-precision turning and repair processing for the surface of the car wheel.

◆The machine tool has also the function of the general CNC lathes.

About HAISHU Machinery

Haishu Machinery is specialized in designing, manufacturing and supplying wheel CNC machine, car wheel CNC lathe machine, alloy wheel repair lathe, precision wheel repair lathe, automatic wheel CNC lathe, wheel CNC lathe with probe, rim straightening machine, brake drum lathe and automatic wheel production line. In recent years, we have been keeping on investing in technological innovation, CNC software development and automatic production line integration technology. All the customer requirements from different fields and industry can be satisfied by our solid technologies and professional staffs.