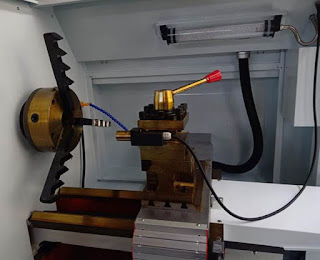

Small automatic wheel polishing lathe CK6160Q is a specially engineered and fabricated wheel CNC machine by Haishu Machinery for alloy car wheel repair and maintenance in Car Repair Workshops. Our small CNC wheel repair lathe CK6160Q features self developed CNC system, high efficiency, compact structure, touch screen, easy to operate. the wheel CNC machine CK6160Q is the light machine. You can choose the chuck or mandrel as a fixture.

Wheel CNC Machine CK6160Q Technical Parameters

| Item | Unit | Specifications |

| Max Wheel Diameter | inch | 24″ |

| X-axis maximum stroke | mm | 320 |

| Main motor power | kw | 3 |

| Rail Width | mm | 260 |

| Wheel measuring direction | X,Z | |

| Measuring Tool | Laser or probe (optional) | |

| Measurement method | Point measurement and quick scan | |

| Program optimization | Manual and automatic | |

| Number of wheel processing programs | rows | 100000 |

| CNC System | “HAISHU” special system (touch screen operation, 17 “screen LCD display). Universal CNC system (key operation, 10.4 “screen LCD display) (optional) | |

| Wheel processing | Surface, rim | |

| Main drive form | Frequency control, servo drive (optional) | |

| Spindle speed | Factory setting 150~2800 | |

| Fast-moving feed | mm/min | X :5000 Z :8000 |

| Repeat accuracy | mm | X :0.01 Z :0.015 |

| Turret form | Fixed turret,Electric turret (optional) | |

| Section of turning tool | mm | 25×25 |

| Machine size(L×W×H) | mm | 1900×1400×1750 |

| Net weight | kg | 1000 |

Small Automatic Wheel Repair Lathe CK6160Q Features

1.The wheel lathe has the advantages of simple structure, low cost, and high-performance price ratio.

2.The machine tool can be selected by laser scanning or probe click measurement.

3.Wheel data is automatically stored, the machining program is arbitrarily called out.

4.Software independent development, program automatically optimize

5.Wheel processing is automatic precise and fast

6.The machine tool is operated by a touch screen, and the system interface supports many languages.

7.X / Z-axis measurement, wheel surface, and circumferential machining.

8.The wheel machine is equipped with an automatic lubrication system.

9.The lathe with diamond tool turning, make wheel surface more smooth.

10.The wheel repair lathe has the teaching function of the computer.

11.The machine can be customized according to customer requirements.

Mr. Kim is from South Korea and he is a re-seller. He recommended Chinese wheel repair equipment to Korean customers. Of course, he also has his own auto parts company. He used to buy our CK6180A wheel cutting lathe machine, equipped with an SYNTEC CNC system. Later, after we developed the touch screen system, he was very interested and once came to our company for inspection. We tested the working condition of our touch screen system on-site and found the Wheel CNC Machine to be very good. Many of our CK6160Q small automatic wheel polishing lathe exported to South Korea are equipped with laser detection and a gang knife. In order to distinguish from other customers, Kim chose a manual four-station tool holder and a touch probe. He likes this configuration. The detection of the touch probe is more accurate, which has certain advantages for the complex shape of the wheel hub.

Wheel repair lathe should be noted that the speed of the touch probe is much slower than the laser detection, because the laser detection is a scanning type, and the touch probe is a point detection. Of course, Mr. Kim knows this very well.

About Haishu Machinery

Taian Haishu Machinery Co., Ltd. is a professional CNC machine designer and manufacturer dedicated to supplying automobile wheel production and repair solutions to worldwide customers. We have been always worked hard to become the leader in designing and manufacturing CNC lathes since 2001. We have more than 30 talented experts and more than 12,000 square meters factory.

We are looking for partners all over the world.

没有评论:

发表评论