Why is a Diamond Cut CNC Machine Superior for Car Wheel Hub Surface Renovation?

In the automotive maintenance industry, wheel hub refurbishment is an essential process for enhancing vehicle aesthetics and ensuring driving safety. A properly maintained wheel hub not only adds to the visual appeal of a vehicle but also ensures stability and safety during high-speed driving. However, traditional wheel hub repair methods often fall short of meeting today’s high standards due to inefficiency and inconsistent results. The introduction of diamond cut CNC machines has revolutionized the wheel hub repair industry, offering precision, efficiency, and reliability.

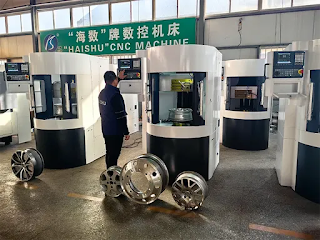

In this article, we’ll explore the superiority of diamond cut CNC machines for wheel hub surface renovation, answering key questions about their advantages. We’ll also introduce Tai’an Haishu, a leading manufacturer of wheel repair machines(Rad reparatu rmaschine), and showcase their flagship products, CKL35 vertical wheel repair lathe and CK6160Q wheel repair lathe (Máquina de Reparo de Rodas), with detailed technical specifications. If you’re looking to upgrade your automotive repair business, Tai’an Haishu’s advanced solutions will help you stand out in this competitive industry.

What Are the Drawbacks of Traditional Wheel Hub Repair Methods Compared to Diamond Cut CNC Machine?

Traditional Methods Lack Precision and Efficiency

Before the widespread adoption of diamond cut CNC machines, wheel hub repair primarily relied on manual grinding or basic mechanical tools. Small repair shops often used hand grinders to address scratches and wear on the wheel hub surface. While inexpensive, this method is highly inefficient, with experienced workers taking hours to restore a single wheel hub. Moreover, the quality of the repair depends entirely on the technician’s skill, leading to inconsistent results that fail to meet modern standards.

Some shops turned to basic horizontal lathes for wheel repair. These machines are limited in functionality, capable only of basic turning operations. They struggle to handle complex wheel hub designs or high-precision requirements. Vibrations and deviations during the machining process often result in a rough wheel hub surface and poor dynamic balance, which can cause vehicle instability and safety risks during high-speed driving.

How Do Diamond Cut CNC Machine Revolutionize Wheel Hub Repair?

Precision and High Accuracy

The diamond cut CNC machine is a game-changer in the wheel repair industry. Unlike traditional methods, CNC machines offer unmatched precision. Tai’an Haishu’s products, such as the CK6160Q wheel repair lathe (Macchina per la Riparazione delle Ruote)and the CKL35 vertical wheel repair lathe (휠 수리 기계), feature positioning accuracy of ±0.01mm. This precision ensures that damaged areas of the wheel hub are removed with pinpoint accuracy while preserving undamaged sections, resulting in a repair that matches the original factory specifications.

In contrast, traditional methods can have errors as large as ±0.5mm. Such deviations can lead to issues like vehicle vibrations, abnormal tire wear, and even safety risks during high-speed driving.

Advanced Detection Systems

Tai’an Haishu’s diamond cut CNC machines come equipped with industry-leading detection systems, offering unmatched convenience and accuracy. The company provides four detection methods:

- Laser Detection: The fastest and most efficient method, completing precise measurements in just 15 seconds.

- Contact-Based Probe Detection: Requires more time, taking over 10 minutes.

- Automatic Tool-Tip Detection: Offers a user-friendly experience, allowing even inexperienced operators to achieve professional-grade results.

- Manual Tool-Tip Detection: Designed for handling unique or complex wheel hub surfaces.

These advanced systems cater to a wide range of customer needs, ensuring precise and efficient wheel hub refurbishment.

Why Should You Choose Tai’an Haishu Diamond Cut CNC Machine?

Outstanding Features of Tai’an Haishu Machines

Tai’an Haishu has invested heavily in designing, developing, and producing cutting-edge wheel repair machines (Machine de Réparation de Roues). Their flagship products, the CK6160Q wheel repair lathe (Tekerlek Tamir Makinesi)and CKL35 vertical wheel repair lathe(Máy Sửa Chữa Bánh Xe), offer industry-leading performance and versatility. Here’s why they stand out:

- High Efficiency: The CK6160Q supports large turning diameters and extended clamps, making it suitable for most wheel hubs on the market, including those under 24 inches. This ensures high efficiency and compatibility with a wide range of wheel hub sizes.

- Customization Options: Tai’an Haishu supports ODM/OEM customization, allowing customers to tailor their machines in terms of language, voltage, and tool configuration.

- User-Friendly Operation: Advanced features like automatic tool-tip detection ensure easy operation, even for beginners.

- Free Upgrades: Existing customers benefit from free system upgrades, ensuring their machines stay up-to-date with the latest technology.

CK6160Q Technical Parameters

- Max Swing Diameter: 600mm

- Max Swing over Cross Slide: 350mm

- Max Processing Diameter: 24 inches

- Spindle Speed: 50-1800 RPM

- Accuracy: ±0.01mm

- Voltage: Customizable

- Clamp Type: Extended clamps for large hubs

The CK6160Q is ideal for repair shops looking for a cost-effective, versatile solution for wheel hub refurbishment.

CKL35 Technical Parameters

- Max Swing Diameter: 800mm

- Linear Guide Rails: Ensures high-speed, precision movements

- Moving Speed: 10m/min

- Spindle Speed: 1000 RPM

- Dual-Column Design: Enhances rigidity and reduces vibrations

- Clamp Type: Horizontal clamping for better stability

- Video Monitoring: Real-time monitoring of the repair process

The CKL35 is perfect for shops requiring high-speed operations and the ability to handle larger or more complex wheel hubs.

How Can Tai’an Haishu Diamond Cut CNC Machine Benefit Your Business?

Save Time and Increase Productivity

In the highly competitive automotive repair industry, time is money. The high processing speed and efficiency of Tai’an Haishu’s diamond cut wheel lathe machines ensure quick turnaround times, allowing you to serve more customers and grow your business.

Achieve Consistent High Quality

The precise processing capabilities of wheel CNC machines like the CK6160Q and CKL35 ensure consistent, high-quality results. This helps establish your reputation as a reliable service provider, attracting more customers in the long run.

Cater to Diverse Customer Needs

With customizable features, Tai’an Haishu’s machines can adapt to a wide variety of customer requirements. Whether you’re repairing a 16-inch car wheel or a 24-inch truck wheel, Tai’an Haishu’s machines can handle it all.

Stand Out in the Market

By investing in advanced vertical wheel repair lathes (آلة إصلاح العجلات ) and diamond cut CNC machines, you’ll set yourself apart from competitors still relying on outdated methods. Tai’an Haishu’s state-of-the-art technology and customer support will position your business as an industry leader.

Why Choose Tai’an Haishu for Your Wheel Repair Needs?

Tai’an Haishu is a trusted manufacturer with years of experience in the wheel hub repair industry. Their products, such as the CK6160Q and CKL35, are designed with precision, efficiency, and user-friendliness in mind. Here’s why customers choose Tai’an Haishu:

- Industry-Leading Technology: With their proprietary CNC systems and advanced detection methods, Tai’an Haishu’s machines deliver unparalleled performance.

- Customer-Centric Approach: From free system upgrades to customizable features, Tai’an Haishu goes above and beyond to meet customer needs.

- Comprehensive Support: A professional technical team and after-sales service system ensure smooth operation and long-term reliability.

Conclusion: Upgrade Your Business with Tai’an Haishu Diamond Cut CNC Machines

Don’t let outdated repair methods hold your business back. Invest in Tai’an Haishu’s diamond cut CNC machines, such as the CK6160Q and CKL35, to unlock new levels of precision, efficiency, and profitability. With advanced features, customizable options, and unmatched technical support, Tai’an Haishu is the partner you need to stay ahead in the competitive automotive repair market.

Choose Tai’an Haishu today and take your wheel hub repair business to the next level! Contact us to learn more about our innovative wheel repair machines(Машина для ремонта колес), diamond cut wheel lathe machines, and vertical wheel repair lathes. Let Tai’an Haishu’s cutting-edge technology and customer-first approach help you achieve success in this rapidly evolving industry.