Diamond Cutting Alloy Wheel CNC Lathe CK6166Q is a medium-sized wheel repair lathe.CK6166Q has a detection scanning automatic programming wheel drawing machine. Alloy Rim Repair CNC Lathe function is further improved on the basis of the original programming automatic wheel turning machine. No need for manual programming to measure curves that can be realized fully automatic. Our wheel repair lathe has fast operation speed and simple operation. Not only high efficiency but also easy to learn. Even if have no operating experience, you can quickly master the operation. Various precision indicators that meet or exceed The level of similar foreign machine tools are the first choice for the automotive industry to process wheel parts. This Alloy Wheel Surface Repair lathe CK6166Q is suitable for machining up to 22-inch wheels.

This customer has already bought a wheel CNC lathe last year, now he wanted to buy more same machine Diamond Cutting Alloy Wheel CNC Lathe CK6166Q. He felt satisfied with the size and appearance of Alloy Wheel CNC Lathe CK6166Q and was very happy with the ease of operation. Now he is very proficient in machine operation, and he recognizes our product quality and service very much, so there are not too many problems, so he decided to purchase three more wheel repair lathes. It’s just that he wanted us to give his machine a little sense of design on the sheet metal to highlight the special features of his machine, and our engineer quickly gave him a satisfactory design. He asked for a contract directly and arranged to pay the deposit.

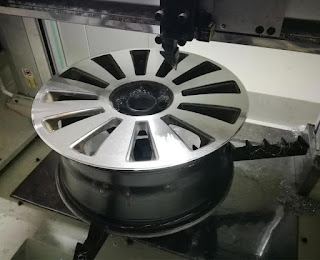

After the Diamond Cutting Alloy Wheel CNC Lathe CK6166Q was completed, We sent them the Wheel CNC Lathe CK6166Q test video and detailed pictures. He was very satisfied.

Main features of Diamond Cutting Alloy Wheel CNC Lathe CK6166Q

Wheel surface measurement using laser scanning, measurement can be a point, it can also be a straight line or curve;

Data is automatically stored. Program optimization can be automatic, can also be manual, and the operation is simple and free.

The spindle is the servo motor drive, synchronize belt, and machine shaft all the realization of digital drive to ensure the accuracy of the machine.

CNC system and program optimization software are developed by the company, specifically for the wheel repair, the specialty is strong and full-featured.

Wheel measurement data can be stored at random, When the same type of wheel repair, do not repeat the measurement, directly out of the program for wheel repair. System hard disk storage capacity, you can store 100,000 wheel program, the use of very convenient.

The machine uses a touch screen operation, supports a variety of national languages, and can also set the language according to customer requirements.

The wheel CNC lathe machine can be measured on the X / Z axis to achieve the machining and repair of the wheel surface and rim.

Machine specifications are complete, wheel diameter can be arbitrarily selected in the range of 5 “to 35”.

Wheel CNC lathe machine is equipped with a new full protective cover, rail sliding doors, working space is large, easy to operate.

The safety fault alarm light.

Automatic lubrication system.

Diamond cutting, to achieve the wheel surface polishing processing.

The machine can be customized according to customer requirements.

|

Technical Parameters of Diamond Cutting Alloy Wheel CNC Lathe CK6166Q

| Project name | Unit | Technical paramaters |

| Max. wheel diameter | Inch | 22″ |

| Max. workpiece length | mm | 750 |

| Probe measuring direction | X,Z | |

| Probe needle | mm | φ3 × 40, φ6 × 50, or optional |

| Machning accuracy | IT6~IT7 | |

| Surface roughness | um | Ra0.8~1.6 |

| Main transmission form | Independent spindle; frequency conversion stepless | |

| Range of spindle speed | rpm | 150~2800 |

| Main motor power | kw | 5.5 |

| Fast-moving feed | mm/min | X – axis:5000 Z – axis:8000 |

| Repeat positioning accuracy | mm | X – axis:0.01 Z – axis:0.015 |

| Turret form | 4 station electric turret | |

| Repeat positioning accuracy | mm | 0.008 |

| Section of turning tool | mm | 25×25 |

| The size of the machine (L×W×H) | mm | 2100×1500×1880 |

| Net weight of the machine | 2200Kg |

About Haishu Machinery

Haishu Machinery has independent technology development departments to develop products in equipment production, and professional technicians with excellent services. We provide Diamond Cutting Alloy Wheel CNC Lathe CK6166Q, Wheel repair Lathe, Wheel straightening machine, brake drum lathe, etc. for automobile rear market terminal stores, and can customize the shape and color of the wheel machine and also configuration, which is welcomed and praised by large customers. Our company follows the principle of “material, material, telling the truth, truthful work”, with a flexible business model, and high-quality service to customers. Look forward to working with you!